Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

HN-6877 have good air permeability and good stretch, can be use in applications where sound permeation and high stretch is needed.

HN-6877 have good air permeability and good stretch, can be use in applications where sound permeation and high stretch is needed.

Properites

| Article | Width | Gauge | Softening Point | Temperature | Pressure | Recovery | Hand | Modulus (40%) | Modulus (100%) | Wash |

|---|---|---|---|---|---|---|---|---|---|---|

| 6877 | 1500mm | 0.7mm | 120℃ | 140-170℃ | 3.5-5kg | 99% | Medium | / | / | Up to 60'C |

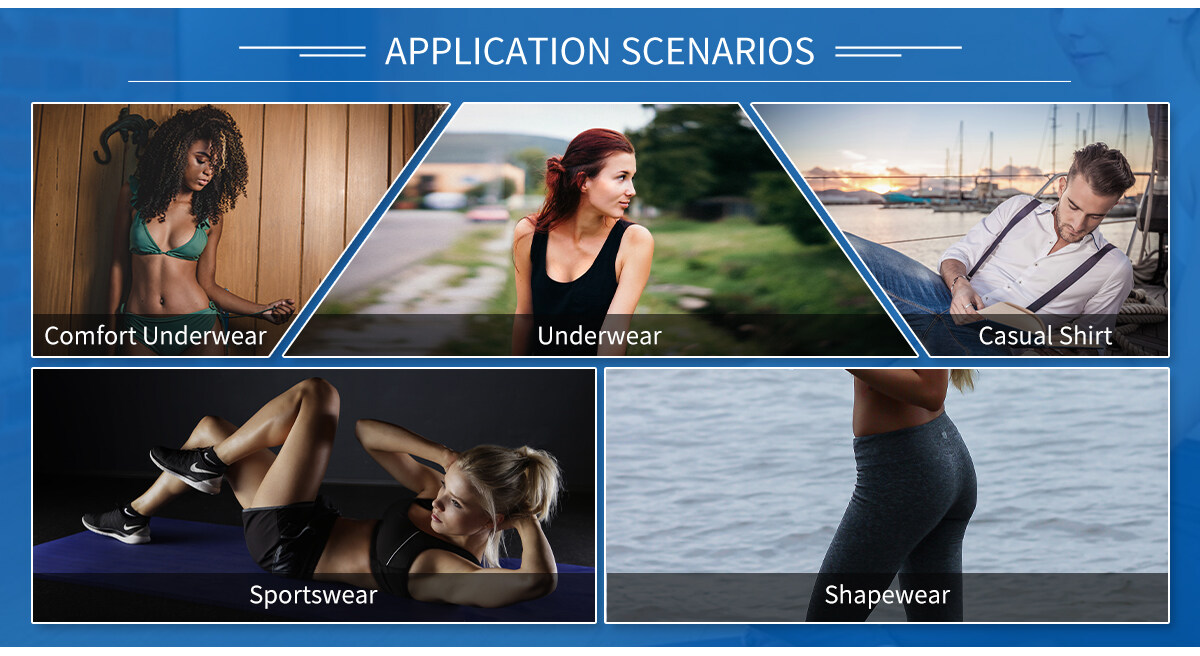

Application of mesh adhesive tape

The production process of yoga pants is slightly different from the pants we usually wear. Yoga pants, like seamless underwear, use a seamless fit production process, which is seamlessly stitched without tightness. In addition, since yoga pants are mainly made of highly elastic fabrics, the Mesh Adhesive that needs to be used has relatively high elasticity.

1. Excellent elasticity

Superior stretch and resilience, excellent extensibility, allowing the fabric to better fit the body curve.

2. Soft and skin-friendly

The hot-melt adhesive film has a soft and delicate feel, which complements the material of the yoga pants, making them comfortable to wear without restraint.

3. Low melting point

Low-temperature operation is not easy to cause damage to the bonded clothing, which is suitable for close-fitting materials such as yoga pants.

4. Good water resistance

The seamless glue is firm, washable, and not degummed.

5. Environmental protection and health

Environmentally friendly materials, non-toxic and tasteless, can directly into contact with human skin.

The production process is different

The hot-melt adhesive mesh film is made by melting the hot-melt adhesive through an extruder and then using the method of melt-blown netting; while the hot-melt adhesive film is made by melting the hot-melt adhesive through an extruder and then using a scraper, Laminating machine or blow molding machine made.

The air permeability is different

The structure of the hot melt adhesive mesh film determines that it is a product with good air permeability, which can be used in cloth bonding in the field of clothing and can still maintain the air permeability of the cloth after bonding; while the hot-melt adhesive film has good air permeability. It is not as good as omentum, so its manufacturing process is to directly make it into the shape of a film, and it will block the fabric mesh after lamination.

The viscosity is different

Usually, the hot melt adhesive film is more viscous than the hot melt adhesive mesh film. This is not just a problem of the high weight of the hot melt adhesive film, because, in the structure of the hot melt adhesive film, there is a gap between the glue molecule and the glue molecule. It is closely connected, and there will be a certain gap between the glue molecules of the hot melt adhesive mesh film.